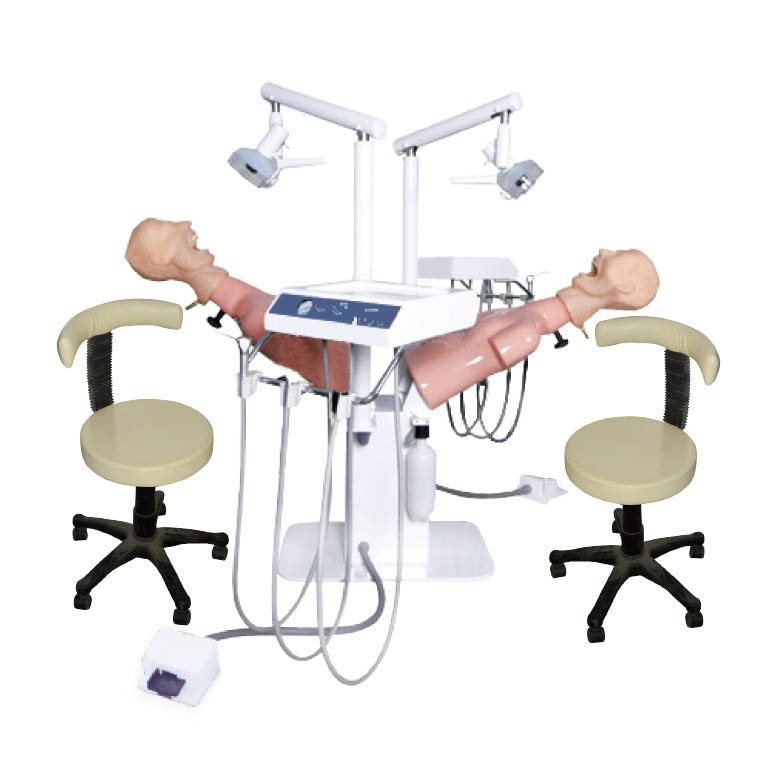

The Phantom Head should allow 3-dimensional movements with human like head rotation

Dental training system completes with phantom head (Torso type) with sophisticated exchangeable articulator condylar movement for allowing threedimensional protrusive, mediotrusive and laterotrusive excursions. : The inclination of condylar guidance should be adjustable on both sides thus allowing the ideal anterior and canine guidance or a fully balanced occlusion to be simulated. The basic geometric dimensions could be able to be measured with compasses and models transferred to partial and fully adjustable articulators. It should be provided with corresponding fixing pins at the hinge-axis points for mounting of anatomical face bows and hinge-axis localizers. Neck movement should be in the anatomically correct position.

Dental model i.e. articulating upper and lower model jaws (32 screw in teeth) and elastic removable gingiva.

Face mask with water drainage nozzle and removable elastic tongue Mounting assembly for fixing to the tableside or to a container. Simulators positioning: Controls pneumatic/motorized.

DELIVERY ARM AND INSTRUMENT ATTACHMENTS

- DELIVERY ARM The delivery arm should have overhead / Top-side access

- It is possible to adjust the height of the delivery arm

- Control of Phantom Positioning: Pneumatic/motorized

- Instrument delivery arm can be balanced with easy maneuverability

- Attached tray for keeping instruments which is scratch, staining and burns resistant

- Operator: Automatic controls (lift to activate)

- Air-rotor attachment with two autoclavable handpieces having in built antiretraction device & quick change. (Warranty of 1 year for handpiece)

- Micromotor with autoclavable straight and contra angled handpiece. The speed range from 100 to 40,000 rpm

- Polymertization Unit: LED Polymerization light preferably with different curing modes, autoclavable light guide, with protective shield and adjustable audible timer.

- ASSISTANT Automatic controls (lift to activate)

– Low volume suction, High volume suction, 3-way syringe. - TOUCH PAD Digital Touchpad has control of the following :

– Operating light, Instrument attachments, Simulator positioning, Controls the speed of micromotor. - FOOT CONTROL Should control working of instruments (Airrotor / Micromotor)

SIMULATOR OPERATING LIGHT

- Shadowless, cold operating light with maximum light intensity upto maximum of 30000 LUX

- The operating light should be stably mounted with enough arm length for both left and right handed operators

- It is drift-free

- Autoclavable handle cover.

- On/off switching can be controllable from operating light as well as simulation unit

- There should be provision for intensity adjustment.

WORK BENCH DESIGN

- Dimensions : customized as per institutional master plan

- Corian top which is scratch, staining and burns resistant

- It has back shelf on work surface with electrical sockets (15 Amp +5 Amp 3 pin socket).

- 3-4 lockable drawers with master key

OPERATOR’S STOOL

- Ergonomically designed operator’s stool with backrest

- Pneumatic cylinder, Seamless upholstery on five casters

- Noise free movements

SUCTION UNITS/COMPRESSOR UNIT

- Drainage system for every individual unit which will include both inlet/outlet of water-compact.

- Compatibility to centralized compressor and vacuum system

- COMPUTER SCREEN Attached LED Screen HDM1 and wifi enable (minimum size 15 inches) with each simulator.